hardness tester vickers 30|vickers hardness tester shimadzu : fabrication It was decided that the indenter shape should be capable of producing geometrically similar impressions, irrespective of size; the impression should have well-defined points of measurement; and the indenter should have high resistance to self . See more Resultado da We would like to show you a description here but the site won’t allow us.

{plog:ftitle_list}

VerbHub . VerbHub

30 indicates the load used in kgf. 20 indicates the loading time if it differs from 10 s to 15 s. See moreThe Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than . See moreIt was decided that the indenter shape should be capable of producing geometrically similar impressions, irrespective of size; the impression should have well-defined points of measurement; and the indenter should have high resistance to self . See more

To convert the Vickers hardness number to SI units the hardness number in kilograms-force per square millimeter (kgf/mm ) has to be multiplied with the standard gravity See more• Indentation hardness• Leeb Rebound Hardness Test• Hardness comparison• Knoop hardness test• Meyer hardness test See moreWhen doing the hardness tests, the minimum distance between indentations and the distance from the indentation to the edge of the specimen must be taken into account to avoid interaction between the work-hardened regions and effects of the edge. These . See moreIf HV is first expressed in N/mm (MPa), or otherwise by converting from kgf/mm , then the tensile strength (in MPa) of the material can be . See more

The fin attachment pins and sleeves in the Convair 580 airliner were specified by the aircraft manufacturer to be hardened to a Vickers Hardness specification of 390HV5, the '5' meaning five kiloponds. However, on the aircraft flying Partnair Flight 394 the pins were later . See moreThe hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .Vickers hardness testing is vital in assessing critical parts' hardness and wear resistance, such as engine components, gears, and turbine blades. This ensures the reliability and safety of these components under extreme operating .The loads applied vary from 1 to 120 kg; the standard loads are 5, 10, 20, 30, 50, 100, and 120 kg. For most hardness testing, 50 kg is maximum. A Vickers hardness tester should be calibrated to meet ASTM standard E10 .

The ultimate macro-vickers hardness tester is the Wilson VH1150 Macro vickers Hardness Tester. Boasting a unique load range of 300gf – 50kgf, enjoy its user-friendly operation with automatic load selection . 3 – 5 – 10 – 20 – 30 .Wilson VH3100 and VH3300 All-in-One Ordering Part Number Description Request a Quote W3100 Fully-Automatic Vickers tester with macro & micro ranges, Load range 0,05 - 10kgf, High Performance Workstation with DiaMet .

A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 . This is applied under a load P of 500–3000 kg applied for 10–30 . The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements.Max sample size: 30 x 40 mm. A compact automatic tabletop cut-off machine for small labs – ideal for sectioning both materialographic and ceramic specimens. . Dedicated hardness testers for Vickers, Knoop, Brinell and Rockwell testing; Universal hardness testers ; Test blocks, specimen holders, clamps, indenters, lenses and other .

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the .Safety. Our Vickers hardness testers meet all common safety requirements, including limit switches for limitation of the travel distance and collision warning features. During development of our Vickers hardness tester, ZwickRoell particularly emphasizes on the safety of the operator and machine. Furthermore, a user-friendly Vickers hardness tester is characterized by a .The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the indentation left in the surface

Vickers hardness testing is extensively used in the metals and alloys industry to evaluate different metallic materials' hardness, strength, and durability. This instrument helps evaluate metallic components' hardness, strength, and durability, ensuring they meet the required specifications and standards. 2. Automotive and Aerospace

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers. Low-load hardness testing is mainly used for testing of small .An all-in-one solution that delivers structure verification and data in just 30 seconds – ideal for both laboratory and production environments. . For the Vickers hardness test, the measured diagonals should not deviate more than 5.0% from each other. For the Knoop hardness test, the two halves of the long diagonals must not differ by more .

Universal hardness testers are designed for hardness testing according to Brinell, Vickers, Rockwell and Knoop, as well as plastics testing and carbon testing.To cover all of these test methods, the universal hardness testing machine supports a wide load range. ZwickRoell universal hardness testers therefore provide a flexible solution with a load range from 0.3 to .

The FALCON 500 offers a leading technology base for manual, automatic or fully automated testing of Micro and Macro Vickers, Knoop or Brinell assignments. With a wide choices of test force configurations, answering any possible imagination, the FALCON 500 can be completed with fully integrated hardware options to assure a match with the .The Vickers hardness test method entails pressing a diamond indenter in the shape of a right pyramid with a square base and an angle of 136 degrees between opposed faces while applying stress ranging from 1 to 100 kgf on the .Model No. PHT-1900 Features. State of the art, digital portable hardness tester is designed to test the hardness of large hard metal parts. Clean crisp display shows the incredible functions that can only be found on this new portable .

pendulum impact test procedure

A Vickers hardness tester is an instrument suitable for testing the hardness of any metal, very hard or soft, particularly used in laboratory. The Vickers hardness testing method consists of applying a certain force over a diamond .This micro hardness tester features a built-in CCD camera for standardized automatic length measurement. Hardness can be measured simply and accurately with easy-touse PC software. The lineup also includes fully automated (FA) machines equipped with an electrically driven revolver mechanism and electrically driven XYZ.Save Big with 30% Reduced Costs. 100% Confidentiality Guaranteed. Free Consultation Today! . The Vickers hardness test is used across various industries for different applications. Metallurgy: To determine the hardness of metals & their alloys. Manufacturing: In quality control, to ensure components meet the required hardness specifications. .

The Vickers Hardness test, referred to as a microhardness test method, is usually for thin sections, small parts, or case depth work. . (where the dwell time will be 30 seconds). The test forces used in the macro range of this Vickers method are considerably lower than those used in the Brinell method. The usually preferred choice for the . 270 – Hardness value; 30 – Load size kgf; 20 – Load holding time s; 3. Microhardness. . Note: 1. The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers Hardness (1) The geometrical shape of the indentation is always similar, while the .The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The . For microindentation typical loads are very light, ranging from 10gf to 1kgf, although macroindentation Vickers loads can range up to 30 kg or more.A powerful Vickers, Knoop, Brinell and Rockwell hardness testing machine, the DuraVersa-100 gives you micro, macro and universal testing in one fully automatic machine – with a wide load range and many applications, including Jominy testing, for the ultimate in versatility.

CIMETRIX offers the CMX1000 Portable Hardness Rockwell Tester Machine for measuring metal hardness in Rockwell C, Rockwell B, Vickers, Brinell and Shore scales. . 30-159 : 23.8-84.6 : Brass : 40-173 : 13.5-95.3 : Bronze : 60-290 : Copper : 45-315 . Reviews about CMX1000 Portable Hardness Tester Rockwell Brinell Vickers CIMETRIX. Average .The Wilson VH3300 offers an advanced, fully automated hardness tester for fulfilling both Vickers and Knoop hardness testing requirements. Designed for all users from novice to expert, it utilizes quick and straightforward operation without compromising the flexibility required for advanced applications.A load of 30 daN is usually used for metals and their alloys. For ceramics and CMC materials, . Specimens randomly selected and submitted to a Vickers hardness test with a diamond pyramid head of a Duramin-1 Vickers hardness tester (Struers) under a predetermined load .

The DuraVision universal hardness testers for standard load ranges of 0.3-250 kgf or 3-3,000 kgf can be used for Vickers, Knoop, Brinell, and Rockwell tests, as well as for carbon and plastics testing.All methods are covered by the ISO 6506, ISO 6507, ISO 45452, ASTM E384, ASTM E92, ASTM E10, ISO 6508, ASTM E18, DIN 51917 and ISO 2039 standards. The DuraVision .

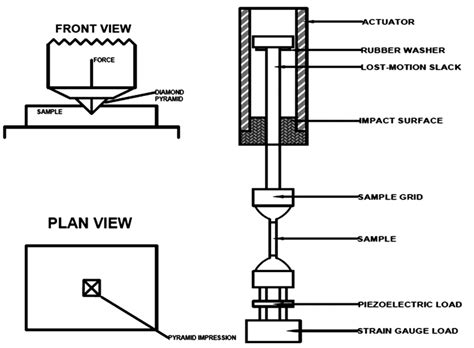

vickers hardness testing machine diagram

vickers hardness tester shimadzu

Resultado da 5 de mai. de 2013 · Você gosta de ver mulheres bonitas e saradas malhando na academia? Então você vai adorar este vídeo, onde uma morena espetacular mostra seus exercícios e seu corpo perfeito. Assista e se .

hardness tester vickers 30|vickers hardness tester shimadzu